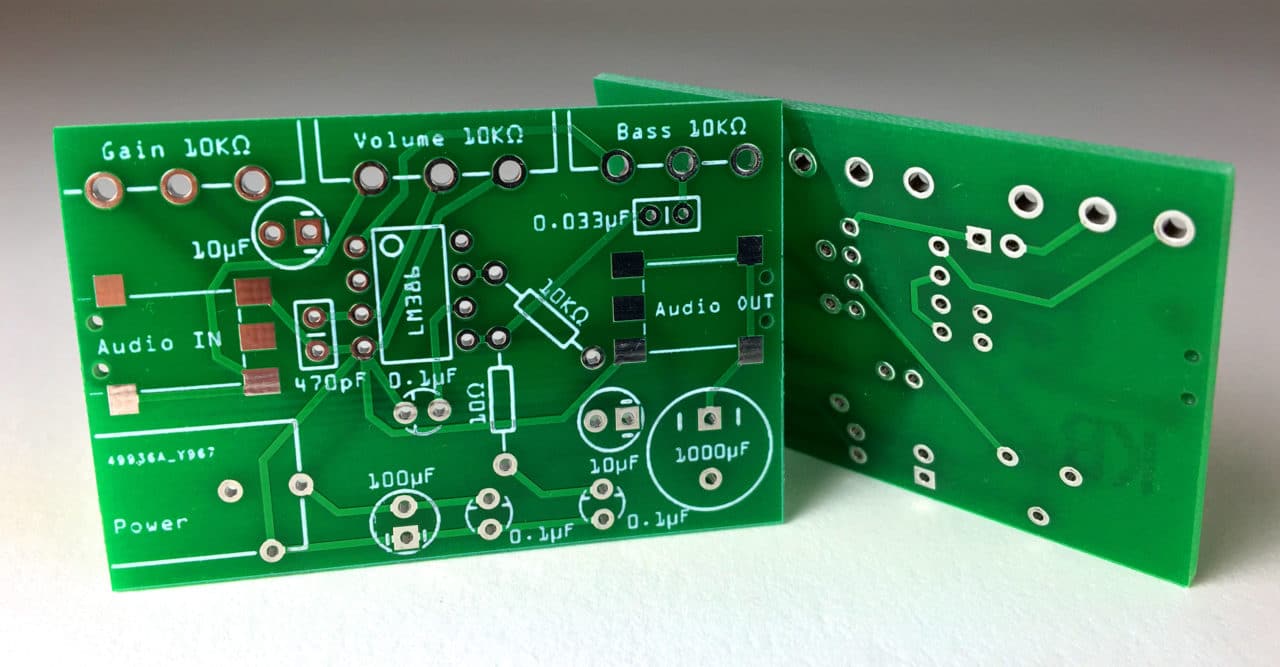

For the uninitiated, printed circuit boards, or PCBs, connect electronic components via conductive rails, pads, and other components. PCBs are in charge of mechanically supporting the product’s electronic components, mostly soldered to the board. Because each electrical product is unique and uses unique components, producing printed circuit boards is highly customizable. This post will go through the manufacturing process in detail, the fundamentals of prototyping, and how to identify a manufacturer for your production needs.

PCB fabrication

Precision is one of the most important aspects of printed circuit boards for electronic production organizations and manufacturers. Printed circuit boards, in general, provide the foundation for assuring product productivity and functionality, and the design of the concerned PCB must be as planned. A PCB prototype is necessary for this purpose. Previous PCB prototypes can be forwarded to the manufacturer for mass production if the product is still in use. On the other hand, new items necessitate the creation of a prototype, which might take a long time and effort.

What Is the Process?

First and foremost, a manufacturer who specializes in prototypes must be found. Prototypes of the essential printed circuit boards are made and tested on several levels long before the production process ensures function and functionality. Making the prototype may take longer than usual, depending on the PCB’s complexity. After a PCB prototype has been completed, third-party services often further test it before being shipped to production. Only a few manufacturers have the engineering capabilities and ability to develop PCB prototypes. The decision must be made carefully because the final product’s entire operation and other elements depend on it. Producing the PCB prototype usually takes longer and costs more money than real production.

Choosing a Business

Many organizations specialize in making printed circuit boards, and you can count on them to provide the best service. Before you choose one, look into their areas of expertise as well as the types of clientele and projects they’ve worked on in the past. Before placing an order, it’s also crucial to learn about their infrastructure and manufacturing capabilities. After all, printed circuit boards are all about performance, and you want a provider that can guarantee quality, function, and features with no sacrifices. Of course, one of the numerous factors to examine is the cost of production, and even more importantly, strategies to lower overall expenditures. Check to see whether you can obtain a discount for large orders, and get an estimate ahead of time to compare your options. When it comes to printed circuit boards, you need to go with a reputable brand, even if it means spending a little extra. Making a printed circuit board is simple for the do-it-yourselfer, thanks to internet instructions and components accessible for purchase. However, the procedure is time-consuming, and making your own PCBs is simply not cost-effective if you require a large number of them.

Now is the time to go online and look for PCB assembly and manufacturers, and don’t forget to ask questions.