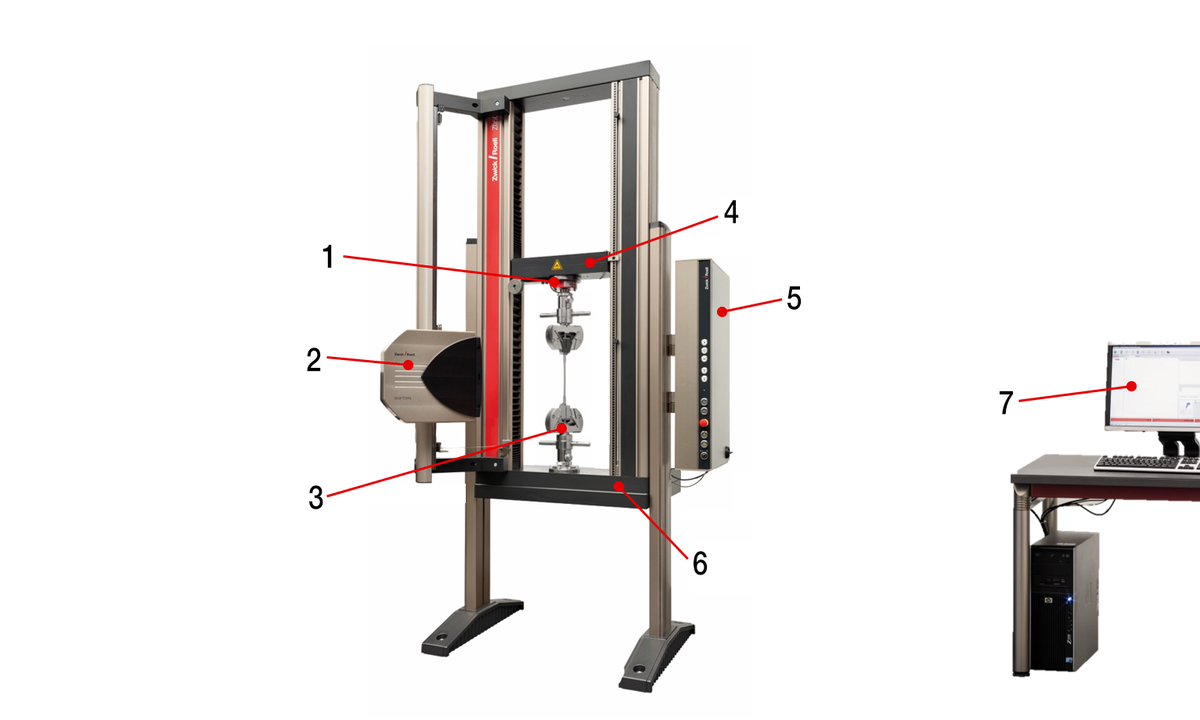

A tensile testing machine is essential for assessing material ductility, which refers to a material’s ability to deform without breaking. Tensile testing machine applies force to a material while measuring its elongation and deformation until failure. This process helps engineers understand how much strain a material can endure before fracturing. Testing material ductility is crucial in industries like construction, aerospace, and manufacturing, where flexible yet strong materials are needed to ensure product safety and reliability.

Here are five ways a tensile testing machine assesses material ductility.

Measures elongation at break

The tensile testing machine measures the elongation of a material at the point of failure. As the machine pulls the material, it stretches, and the machine records the extent to which the material can elongate before breaking. This measurement helps determine the material’s ductility by showing how much it can stretch while maintaining its integrity.

Tracks permanent deformation

A tensile testing machine also tracks the permanent deformation of a material. After applying a tensile force, some materials do not return to their original shape. The machine measures this irreversible change in length, which indicates how much plastic deformation the material can undergo before fracturing. This is key to understanding material ductility.

Determines reduction in cross-section area

During tensile testing, the cross-sectional area of a material often reduces as it stretches. The tensile testing machine measures this reduction, and the data collected helps determine the material’s ductility. A significant reduction in the cross-sectional area indicates that the material has a high level of ductility, as it can thin and deform before breaking.

Monitors stress-strain behavior

The tensile testing machine continuously monitors the stress-strain behavior of a material throughout the test. By observing the relationship between applied stress and resulting strain, engineers can assess how the material behaves under tension. The more strain a material can withstand before reaching its ultimate strength, the more ductile it is considered to be.

Evaluates toughness

Toughness is the ability of a material to absorb energy before fracturing. The tensile testing machine evaluates toughness by measuring both the material’s strength and its ductility. Ductile materials tend to absorb more energy, making them less likely to crack under pressure. This evaluation is important for selecting materials that need to withstand harsh conditions.

To conclude

Tensile testing machines play a vital role in assessing material ductility by measuring elongation, permanent deformation, cross-sectional area reduction, stress-strain behavior, and toughness. These tests help industries ensure that materials can perform safely and reliably under various stresses.